DELTA THERM The leader in manufacturing of high quality temperature sensors for over 18 years. With it’s strong experience & technological skills, it has succeeded in building strong relationship with more than 500 customers all over EGYPT. Our exhaustive range of products provide solutions to conventional temperature sensors to high-tech industrial thermocouples for a variety of industries like Steel, Glass, Power, Cement, Chemicals and many other OEM’s. Our state-of-the-art manufacturing unit located in Kolkata is equipped with modern equipments & testing systems, which not only assembles sensors, but provides temperature solutions to the Industries. Constant upgradation to the newer technology & measuring systems along with proven past records makes us leader in the field of temperature measurement.

Thermocouple consists of two dissimilar conductors in contact, which produce a voltage when heated. The size of the voltage is dependent on the difference of temperature of the junction to other parts of the circuit. Thermocouples are a widely used type of temperature sensor for measurement and control and can also be used to convert a temperature gradient into electricity. Commercial thermocouples are inexpensive, interchangeable, are supplied with standard connectors, and can measure a wide range of temperatures. In contrast to most other methods of temperature measurement, thermocouples are self powered and require no external form of excitation. The main limitation with thermocouples is accuracy; system errors of less than one degree Celsius (°C) can be difficult to achieve.

Any junction of dissimilar metals will produce an electric potential related to temperature. Thermocouples for practical measurement of temperature are junctions of specific alloys which have a predictable and repeatable relationship between temperature and voltage. Different alloys are used for different temperature ranges. Properties such as resistance to corrosion may also be important when choosing a type of thermocouple. Where the measurement point is far from the measuring instrument, the intermediate connection can be made by extension wires which are less costly than the materials used to make the sensor. Thermocouples are usually standardized against a reference temperature of 0 degrees Celsius; practical instruments use electronic methods of cold-junction compensation to adjust for varying temperature at the instrument terminals. Electronic instruments can also compensate for the varying characteristics of the thermocouple, and so improve the precision and accuracy of measurements.

Principle

Thermocouples convert thermal potential variation into electric potential variation. An electromotive force is generated when the ends of 2 wires of dissimilar metals are joined at a temperature other than 0°C (hot junction) while the other ends (cold junction) are set at 0°C (real or compensated value).

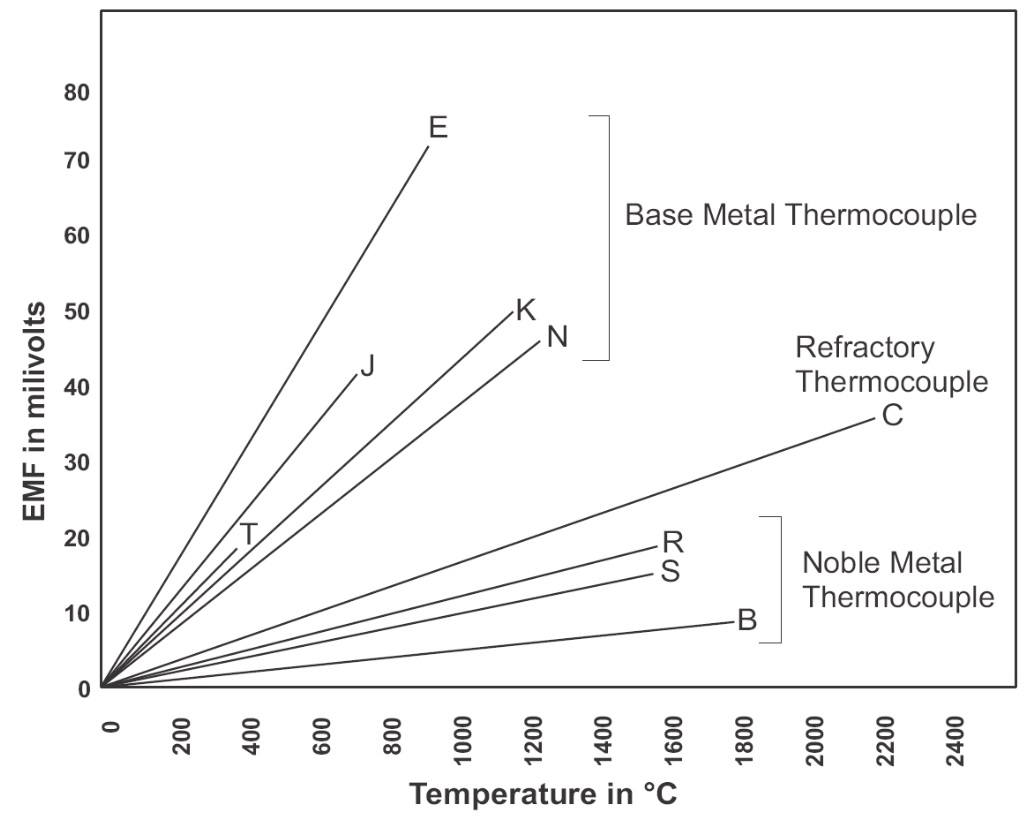

Certain combinations of alloys have become popular as industry standards. Selection of the combination is driven by cost, availability, convenience, melting point, chemical properties, stability, and output. Different types are best suited for different applications. They are usually selected on the basis of the temperature range and sensitivity needed. Thermocouples with low sensitivities (B, R, and S types) have correspondingly lower resolutions. Other selection criteria include the inertness of the thermocouple material, and whether it is magnetic or not. Standard thermocouple types are listed below with the positive electrode first, followed by the negative electrode.

K

Type K (chromel {90% nickel and 10% chromium}—alumel {95% nickel, 2% manganese, 2% aluminium and 1% silicon}) is the most common general purpose thermocouple with a sensitivity of approximately 41 µV/°C, chromel positive relative to alumel.[9] It is inexpensive, and a wide variety of probes are available in its −200 °C to +1250 °C / -330 °F to +2460 °F range. Type K was specified at a time when metallurgy was less advanced than it is today, and consequently characteristics may vary considerably between samples. One of the constituent metals, nickel, is magnetic; a characteristic of thermocouples made with magnetic material is that they undergo a deviation in output when the material reaches its Curie point; this occurs for type K thermocouples at around 350 °C . Wire color standard is yellow (+) and red (-).

E

Type E (chromel–constantan)[6] has a high output (68 µV/°C) which makes it well suited to cryogenic use. Additionally, it is non-magnetic. Wide range is −50 to 740 °C and Narrow range is −110 to 140 °C. Wire color standard is purple (+) and red (-).

J

Type J (iron–constantan) has a more restricted range than type K (−40 to +750 °C), but higher sensitivity of about 55 µV/°C.[2] The Curie point of the iron (770 °C)[10] causes an abrupt change in the characteristic, which determines the upper temperature limit.

N

Type N (Nicrosil–Nisil) (nickel-chromium-silicon/nickel-silicon) thermocouples are suitable for use between −270 °C and 1300 °C owing to its stability and oxidation resistance. Sensitivity is about 39 µV/°C at 900 °C, slightly lower compared to type K.

Designed at the Defence Science and Technology Organization (DSTO), Australia, by Noel A Burley, type N thermocouples overcome the three principal characteristic types and causes of thermoelectric instability in the standard base-metal thermo element materials:

- A gradual and generally cumulative drift in thermal EMF on long exposure at elevated temperatures. This is observed in all base-metal thermo element materials and is mainly due to compositional changes caused by oxidation, carburization or neutron irradiation that can produce transmutation in nuclear reactor environments. In the case of type K, manganese and aluminum elements from the KN (negative) wire migrate to the KP (positive) wire resulting in a down-scale drift due to chemical contamination. This effect is cumulative and irreversible.

- A short-term cyclic change in thermal EMF on heating in the temperature range ca. 250–650 °C, which occurs in types K, J, T and E thermocouples. This kind of EMF instability is associated with structural changes like magnetic short range order.

- A time-independent perturbation in thermal EMF in specific temperature ranges. This is due to composition-dependent magnetic transformations that perturb the thermal EMFs in type K thermocouples in the range ca. 25-225 °C, and in type J above 730 °C.

Nicrosil and Nisil thermocouple alloys show greatly enhanced thermoelectric stability relative to the other standard base-metal thermocouple alloys because their compositions substantially reduces the thermoelectric instability described above. This is achieved primarily by increasing component solute concentrations (chromium and silicon) in a base of nickel above those required to cause a transition from internal to external modes of oxidation, and by selecting solutes (silicon and magnesium) that preferentially oxidize to form a diffusion-barrier, and hence oxidation inhibiting films.

Platinum types B, R, and S

Types B, R, and S Thermocouples use platinum or a platinum–rhodium alloy for each conductor. These are among the most stable thermocouples, but have lower sensitivity than other types, approximately 10 µV/°C. Type B, R, and S thermocouples are usually used only for high temperature measurements due to their high cost and low sensitivity.

B

Type B thermocouples use a platinum–rhodium alloy for each conductor. One conductor contains 30% rhodium while the other conductor contains 6% rhodium. These thermocouples are suited for use at up to 1800 °C. Type B thermocouples produce the same output at 0 °C and 42 °C, limiting their use below about 50 °C.

R

Type R thermocouples use a platinum–rhodium alloy containing 13% rhodium for one conductor and pure platinum for the other conductor. Type R thermocouples are used up to 1600 °C.

S

Type S thermocouples are constructed using one wire of 90% Platinum and 10% Rhodium (the positive or “+” wire) and a second wire of 100% platinum (the negative or “-” wire). Like type R, type S thermocouples are used up to 1600 °C. In particular, type S is used as the standard of calibration for the melting point of gold (1064.43 °C).

T

Type T (copper – constantan) thermocouples are suited for measurements in the −200 to 350 °C range. Often used as a differential measurement since only copper wire touches the probes. Since both conductors are non-magnetic, there is no Curie point and thus no abrupt change in characteristics. Type T thermocouples have a sensitivity of about 43 µV/°C.

C

Type C (tungsten 5% rhenium – tungsten 26% rhenium) thermocouples are suited for measurements in the 0 °C to 2320 °C range. This thermocouple is well-suited for vacuum furnaces at extremely high temperatures. It must never be used in the presence of oxygen at temperatures above 260 °C.

Thermocouples produce a voltage output that can be correlated to the temperature that the thermocouple is measuring. The documents in the table below provide the thermoelectric voltage and corresponding temperature for a given thermocouple type. Most of the documents also provide the thermocouple temperature range :-

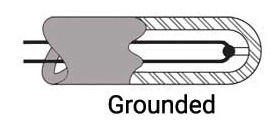

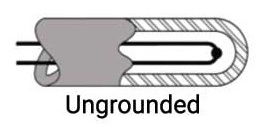

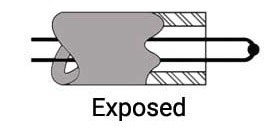

Measuring junctions :

Grounded : With single or dual element. This provides fast response with protection from the process.

Ungrounded : Improved protection from interference that may be picked up by the sheath. Response time may be slower.

Exposed : Very fast response time. Not suitable for many processes because of corrosion.

| Common Materials Protection Tube | |

| Materials | Characteristics |

| Type 304 | Up to 1650 F (900 C) under oxidizing conditions. Has generally good oxidation and corrosion resistance in a wide range of industrial environments. Subject to carbide precipitation, which can reduce corrosion resistance, in the 800-1000 F (430-540 C) range. Good Mechanical properties from – 300 to 1450 F ( – 185 to 790 C). Main areas of usage: chemicals, foods, plastics, petroleum. Generally regarded as a standard protection tube material. |

| Type 310 | Up to 2100 F (1150 C) under oxidizing conditions. Power plant boiler tubes to 1800 F (980 C) are main area of application. |

| Type 316 | Up to 1700 F (930 C) under oxidizing conditions. Same areas of application as type 304, plus improved resistance to acid and pitting corrosion |

| Type 446 | Up to 2000 F (1090 C) under oxidizing conditions. Excellent high temperature corrosion and oxidation resistance. Main areas of application are hardening, nitriding, and annealing furnaces: salt baths, molten lead; tin and Babbitt metal-, sulfurous atmospheres. Not for carburizing atmospheres. Other areas are steel soaking pits, tinning pots, waste heat boilers, ore roasters, cement exit flues, boiler tubes to 1800 F (980 C), asphalt mixing incinerators to 2000 F (1090 C), glass tank flues. |

| Inconel 600 | Up to 2100 F (1150 C) under oxidizing conditions. Reducing conditions lower maximum temperature to 1900 F (1040 C). Must not be placed in sulfurous atmospheres above 1000 F (540 C). Main areas of application. carburizing, annealing, and hardening furnaces, cyanide salt baths; blast furnace downcomers; open hearth fluestacks, steel soaking pits, waste heat boilers-, ore roasters-, cement exit flues-, incinerators, glass tank flues. |

| Inconel 601 | Similar applications to Inconel 600, but with superior resistance to sulfur and high temperature oxidation resistance to 2300F(1260C). |

| Incoloy 800 | Up to 2000 F (1090 C) in oxidizing conditions. Similar to Inconel, but less suitable in nitriding and molten caustics. Superior resistance to sulfur than Inconel 600. |

| Kanthal A-1 | Up to 2300 F (1260 C) in oxidizing conditions. Good high temperature sulfur resistance. Free halogens and alkalis, or their compounds, reduce corrosion resistance severely. |

| Nickel | Up to 2100 F (1150 C) under oxidizing conditions. Must not be placed in presence of sulfur above 1000 F (540 C). Main areas of application are potassium cyanide salt baths, brines, caustics, high temperature chemical exposure. |

| Carbon steel (C1018) | Up to 1000 F (540 C) in nonoxidizing environments. Main areas of usage are galvanizing pots, tinning pots, molten babbit metal, molten magnesium, molten zinc, petroleum refinery applications such as dewaxing and thermal cracking. |

| Low alloy steel (Yoloy) | Up to 1250 F (680 C) in noncorrosive environments. Somewhat superior to carbon steel; replaces wrought iron. Areas of application are annealing furnaces to 1250 F (680 C), ovens, ceramic dryers, glass tank flues. |

| Cast iron | Up to 1300 F (700 C) in oxidizing conditions. Main area of usage is in molten nonferrous metals: daily whiting is recommended. Can be used to 1600 F (870 C) under reducing conditions. |

| Metal ceramic (LT-1) | Up to 2500 F (1370 C) in oxidizing conditions. Main areas of usage are molten copper-base alloys to 2100 F (1150 C), blastturnace and stack gases to 2400 F (1315 C), sulfur burners to 2000 F (1090 C), cement kilns to 2200 F (1200 C), chemical process reactors to 2500 F (1370 C). A ceramic primary tube is required when noble metal thermocouple is used. |

| Mullite (63% alumina) | Up to 2750 F (1510 C). Has poUp to 3200 F (1760 C). Has only fair resistance to thermal and mechanical shock. Essentially same areas as mullite, including induction melting, vacuum furnaces. or mechanical shock resistance and good thermal shock resistance. For barium chloride salt baths to 2350 F (1290 C), Should be vertically mounted or supported if horizontal. For high temperature applications of ceramic industry, heat treating, glass manufacture. |

| Alumina (96%) | Up to 3200 F (1760 C). Has only fair resistance to thermal and mechanical shock. Essentially same areas as mullite, including induction melting, vacuum furnaces. |

| Alumina (99.5%) | Applications similar to alumina (96%); can be used to 3400 F (1870 C) when properly supported. |

| Silicon carbide | Up to 3000 F (1650 C). For a secondary protection tube with alumina or mullite primary tube. For brick and ceramic kilns, steel soaking pits, molten nonferrous metals. Can withstand direct flame impingement. |

| Quartz | Up to 2000 F (1090 C). Excellent resistance to thermal shock. For molten gold and silver. |