Stainless steel pipe 304

This is the most cost effective grade of steel. So the 304 Stainless Steel Pipe Price is lower compared to other grades of stainless steels and all metallic products in general. There are different versions of the material with low carbon and high carbon content. The Pipes and UNS S30400 Stainless Steel Strip Specification varies and the applications differ for the different versions of the material. The low carbon version, 304L Pipes are very good for welding applications as they have less carbide precipitation and less localized corrosion. The ASME SA240 Stainless Steel 304 Pipe Thickness ranges up to 200mm and the width and the length ranges widely depending on the application requirements as well. Please contact us for more information and prices.

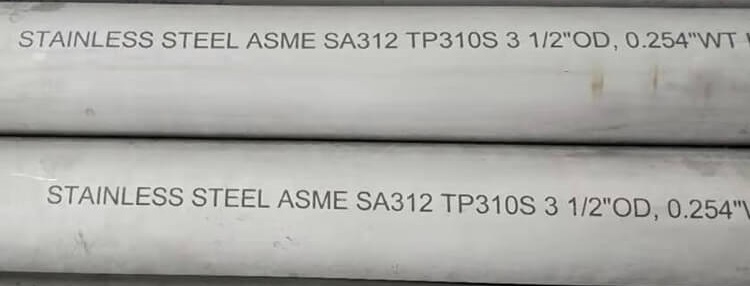

Hollow round bar 310S

Stainless steel is austenitic chromium nickel stainless steel, has good oxidation resistance, corrosion resistance. Because the higher percentage of chromium and nickel, which has much better

creep strength, continuous operation at high temperature, good resistance to high temperature.

When temperature exceeds 1000 ℃, It is initials to be softening, allowable stress continued to decrease, The maximum temperature 1200 ℃. For nickel (Ni), chromium (Cr) content is high, with

good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature performance, high temperature resistant steel for making electro-thermal furnace tube etc..

Increasing the carbon content of austenite stainless steel, because of its solid solution strengthening effect that the intensity is improved, chemical characteristics of austenitic stainless steel is in chromium, nickel based addition of molybdenum, tungsten, niobium and titanium, because its organization is face centered cubic structure, so it has high strength and creep strength at high temperature.

GENERAL PROPERTIES

Alloy 310 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F. Due to its high chromium and nickel content, it is superior to 304 or 309 stainless in most environments.

APPLICATIONS :-

The higher alloyed stainless steels generally have excellent strength at elevated temperatures along with outstanding resistance to creep deformation and environmental attack. Therefore, Alloy 310 is used widely in industries such as heat treatment and chemical processing. Some examples include :

· Furnace Parts

· Oil Burner Parts

· Heat Exchangers

· Welding Filler Wire and Electrodes

· Annealing Covers

· Combustion Tubes

· Fire Box Sheets

Availability – Stainless Steel 310S : Seamless Pipe 1/2″.

Chemical Composition – Stainless Steel 310S

C Cr Mn Mo Ni P S Si

Max Max Max Max Max Max

0.08% 24% – 26% 2.0% 0.75% 19% – 22% 0.045% 0.03% 0.75%

Design Features – Stainless Steel 310S

Austenitic stainless steel with excellent high temperature oxidation resistance.

Good for continuous exposure to 2100 F degree, intermittent service to 1900 F degree.

Better elevated temperature creep strength than the 18-8 grades.

Good resistance to both carburizing and reducing environments.

General corrosion resistance better than Types 304 and 309.

May be susceptibe to chloride stress corrosion cracking.

Ease of fabrication.

Typical Applications – Stainless Steel 310S

Sulfur bearing gas atmospheres

Molten salt applications

Heat exchangers

Heat recuperator tubing

Tensile Requirements – Stainless Steel 310S

Tensile Strength (KSI) : 75

Yield Strength (KSI) : 30

Stainless Steel 446

Stainless Steel 446 is a ferritic, heat resisting, stainless chromium steel, characterized by extremely good resistance to reducing sulphurous gases, very good resistance to oxidation in air, good resistance to oil-ash corrosion, good resistance to molten copper, lead and tin. This steel can be used at temperatures up to 1100°C (2010°F). However, allowance should be made for the low creep strength at the highest temperatures in order to avoid distortion due to the mass of the steel.

Stainless Steel 446 has various applications and can be used to prepare Neutral salt pot electrodes, Remuneration, Spouts for conveying molten copper alloys, Oil burner parts, Combustion chambers, Furnace and kiln linings, Stack dampers, Boiler baffles, Glass molds and Soot blowers, Boiler tubes, preheaters and heat exchangers, Cement kilns, Waste heat boilers, Molten lead, Salt baths, Heat treating, Incinerators.

INCONEL 600

(nickel-chromium-iron) alloy 600 (UNSN06600 / W.Nr. 2.4816) is a standard engineering material for applications which require resistance to corrosion and heat. The alloy also has excellent mechanical properties and presents the desirable combination of high strength and good workability.

The limiting chemical composition of INCONEL alloy 600 is shown in Table.

The high nickel content gives the alloy resistance to corrosion by many organic and inorganic compounds and also makes it virtually immune to chloride-ion stress-corrosion cracking.

Chromium confers resistance to sulfur compounds and also provides resistance to oxidizing conditions at high

temperatures or in corrosive solutions. The alloy is not precipitation hardenable; it is hardened and strengthened only by cold work.

The versatility of INCONEL alloy 600 has led to its use in a variety of applications involving temperatures from cryogenic to above 2000°F (1095°C).

The alloy is used extensively in the chemical industry for its strength and corrosion resistance.

Applications include heaters, stills, bubble towers and condensers for processing of fatty acids; evaporator tubes, tube sheets and flaking trays for the manufacture of sodium sulfide; and equipment for handling abietic acid in the manufacture of paper pulp.

The alloy’s strength and oxidation resistance at high temperatures make it useful for many applications in the heat-treating industry. It is used for retorts, muffles, roller hearths and other furnace components and for heat-treating baskets and trays.

In the aeronautical field, INCONEL alloy 600 is used for a variety of engine and airframe components which must withstand high temperatures. Examples are lockwire, exhaust liners and turbine seals.

INCONEL alloy 600 is used in the electronic field for such parts as cathode-ray tube spiders, thyratron grids, tube support members and springs.

The alloy is a standard material of construction for nuclear reactors. It has excellent resistance to corrosion by high-purity water, and no indication of chloride-ion stress-corrosion cracking in reactor water systems has been detected. For nuclear applications, the alloy is produced to exacting specifications and is designated INCONEL alloy 600T.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.