Product Description

middle-temperature control heating cable (self-regulating heating cable) is widely used in pipelines, storage tanks and civil pipelines of firefighting, petroleum, chemical engineering, steel, power and other industrial enterprises for heat tracing, thermal insulation, anticoagulation and antifreezing. The cable is suitable for common area, the dangerous area and the corrosive area.

Features of heating cable :-

-

Heating cable corresponding to heat tracing system has a feature of automatically adjustment of the output power, Therefore, it will not be burned for self-heating, and able to make thermal compensation according to the actual needs, so it is the energy-saving and intelligent electric heater with only strip thermostat.

-

Low-temperature start quickly, uniform temperature, high-temperature limit temperature automatically, whole or in part can be adjusted automatically with the temperature change of heat tracing, without additional temperature control device.

-

Easy to install and simple to maintain, AC and DC, with wide operating voltage and adaptation, high level of automation, low operating and maintenance costs.

-

can be cut at any length and lengthening use within a certain range, allows multiple overlapping but no high temperature hot point or burning. The application of far-infrared radiation technology for transforming has no damage to human body.

Product Model: ZMK( ZXW;ZKW;ZKWZ;ZBW) Corresponding to foreign models QTVR series

temperature rating: middle temperature( Z) series

structure: base type( J);basic corrosion type (F); Explosion-proof shielding type( P); Explosion enhanced type( PT) explosion-proof and corrosion type( PF)

Voltage grade : 12V; 24V; 36V; 110V; 220V; 380V; 600V.

Rated power : 35 W/m; 45 W/m; 50 W/m; 55 W/m; 60 W/m.

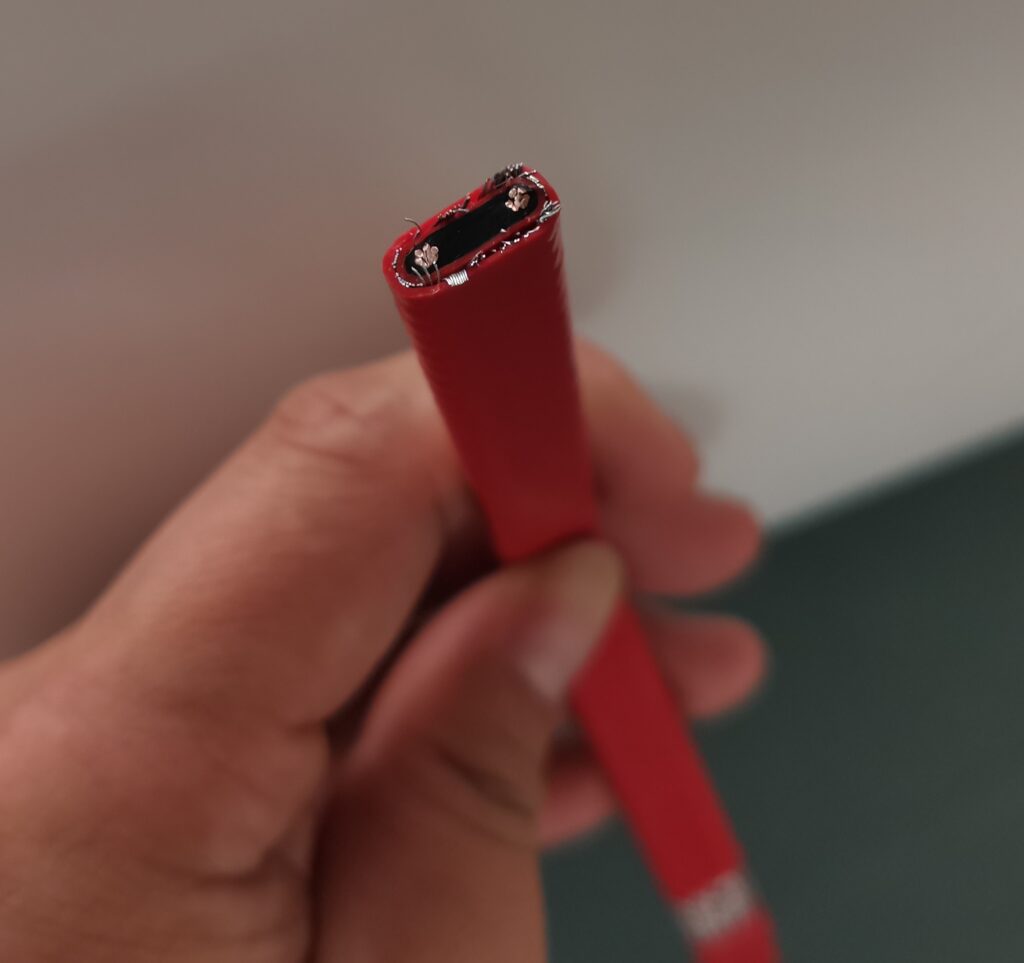

Product structure:

Copper conductor : 7×0.50; 7×0.32; 19×0.41; 64×0.15

The conductive plastic layer : Common PTC; flame retardant PTC; fluorine containing PTC.

The composite insulation layer.

The insulating layer : Modified polyolefin; flame retardant polyolefin; fluorinated polyolefin; perfluorinated materials.

Shielding layer : Tinned round copper wire, the coverage density of 80%.

Sheath layer : Modified polyolefin; flame retardant polyolefin; fluorinated polyolefin; perfluorinated materials.

Technical parameters :-

standard color : brown

the temperature range: maximum temperature 105±5℃; maximum exposure temperature 135℃; maximum withstand temperature: modified polyolefin 105℃; flame retardant polyolefin 105℃; fluorinated polyolefin 180 ℃; perfluorinated material205 ℃; Construction temperature : -40 ℃

The thermal stability : From 10℃ to 149℃ and after 300 cycles, the cable heat to maintain in 90% above.

Bending radius: -20℃-30℃ for 30.4mm and 40.6mm;

The length of the cable insulation resistance:

cable length is 100M, ambient temperature 75 ℃ for 2,500VDC, shake test for 1 minutes, and the minimum value of ( between the shielding layer and the conductive core line ) insulation resistance of 1200MΩ.

Proof mark: ExeⅡT4

Product advantages :-

The temperature of heating pipes is uniform and safe and reliable, it will not overheat.

Saving electric energy

When intermittent operation, temperature rise goes quickly

Low installation and operating costs

Easy to install and convenient to repair;

Convenient for automation management.

No environmental pollution.

Installation Manual of heat tracing cable

No distortion, tangle, repeated bend is allowed when storing, handling, installing or using electric heating cable. Damage of outer sheath or insulation is strictly forbidden

Check the appearance and insulation before laying the electric heating cable. The insulation resistance values shall conform to the values stated in product manual.

When laying the electric heating cable, do not make the hard fold or drag it on the floor at long distance

When fixing the electric heating cable, leave some space for reaction so that it will not break down due to expansion caused by heat or contraction caused by cold, so as to avoid short circuit

The power supply connected to the electric heating cable should be consistent with the work voltage as required

Make sure the voltage is stable to avoid electric heating cable is frequently switched on and off

If the terminal box is installed outdoor, it should be reversely placed in case rainwater dropping into the box, resulting in any safety problem

Follow electric heating cable product property. For example, follow the maximum application length: 100M for industrial application & 30M for civil application while the low-voltage electric heating cable is 30M.

After the electric heating cable is installed, check the circuit safety before installing the insulation layer. Pipe tank with fire resistance and high tracing heat must be used and the insulation material should be cautiously considered & selected

Key points for general installation of electric heating cable:

Electric heating cable should be placed closely beneath the pipe or winded upon the pipe. Use aluminum adhesive tape; for every 0.5~0.8m, use heat-resisting adhesive tape to fix the electric heating cable at the radial direction. The electric tracing cable laid paralleling to pipe is usually installed beneath the pipe, and keep 45°angle to the horizontal axis of the pipe section. If use 2 electric tracing cables, they are required to be symmetrically laid.

The minimum bending radius when install the electric heating cable should be no less than 5-6 times of the thickness.

When connecting the wire, electric heating cable should be correctly secured in place, to avoid short circuit. At the same time, connect the mesh grid to secure the ground connection.

Burr or sharp corner should be removed from the pipe or container surface in order to protect from any damage to tracing heat cable during installation process. The rust-proof and antiseptic coating should be dry; tracing cable model should be consistent with the design requirement

For about every 50cm, fix the electric heating cable onto the dry pipe with fiberglass pressure sensitive tape or aluminum adhesive tape. When laying the electric heating cable, try to attach it at the aposition 45 ° under the pipe

Reserve 1m electric heating cable at the first power supply terminal and the end terminal of the circuit; leave certain length of the electric heating cable at all the radiators such as the stand, valve, flange, etc, in order to make it convenient for removal, maintenance, or replace at any time whenever it is needed.

Wherever there is 2-way or 3-way accessory used, each port should be reserved with 40cm length of the electric heating cable. Power supply point should be reasonably selected for multiple electric heating cables to make maintenance convenient.

Ribbon cable installation should be proceeded with only after the pipeline system is completely installed and it is hydrostatically approved. Construction of insulating layer can only be started after the electric heating cables are completely installed, regulated, tested and proved with normal delivery of current

After the above installation is completed, insulation test should be conducted to make sure the resistance between wire core of the electric heating cable and the mesh grid is consistent with the product manual

Material of the insulation layer should be dry and quality & thickness should be secured. Waterproof cover should be added and caution mark should be indicated with “electric heating cable inside” outside insulation layer

When installing on the container, the electric tracing cable should be winded upon the middle and lower section of the container, usually not exceed 2/3 of the container height, normally 1/3

When install the electric tracing cable, possibility to remove the pipe accessory and equipment should be thoroughly considered, in order to make sure the electric tracing cable will not be damaged

It is required the rubber gasket, washer, and fastener should all be available and in integrity status when installing the accessory. Installation should be correct, secured to avoid loose or water getting into the box

In humid and corrosive environment, enhance.