310S stainless steel is austenitic chromium nickel stainless steel, has good oxidation resistance,

corrosion resistance. Because the higher percentage of chromium and nickel, which has much better

creep strength, continuous operation at high temperature, good resistance to high temperature.

When temperature exceeds 800 ℃, It is initials to be softening, allowable stress continued to

decrease, the maximum temperature 1200 ℃. For nickel (Ni), chromium (Cr) content is high, with

good oxidation resistance, corrosion resistance, acid and alkali resistance, high temperature

performance, high temperature resistant steel for making electro-thermal furnace tube etc..

Increasing the carbon content of austenite stainless steel, because of its solid solution strengthening

effect that the intensity is improved, chemical characteristics of austenitic stainless steel is in

chromium, nickel based addition of molybdenum, tungsten, niobium and titanium, because its

organization is face centered cubic structure, so it has high strength and creep strength at high

temperature.

GENERAL PROPERTIES

Alloy 310 is an austenitic stainless steel that combines excellent high temperature properties with good ductility and weldability. It is typically used for elevated temperature applications as its high chromium and nickel content provide solid corrosion resistance, excellent resistance to oxidation, and superior strength in temperatures up to 2100°F. Due to its high chromium and nickel content, it is superior to 304 or 309 stainless in most environments.

APPLICATIONS:

The higher alloyed stainless steels generally have excellent strength at elevated temperatures along with outstanding resistance to creep deformation and environmental attack. Therefore, Alloy 310 is used widely in industries such as heat treatment and chemical processing. Some examples include:

Furnace Parts

Oil Burner Parts

Heat Exchangers

Welding Filler Wire and Electrodes

Annealing Covers

Combustion Tubes

Fire Box Sheets

310S Stainless Steel

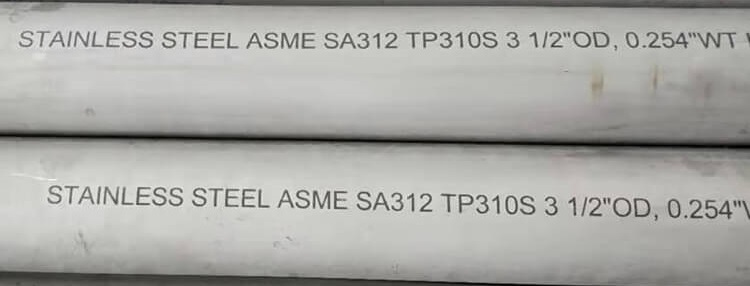

DELTA THERM makes stainless steel 310S pipe according to customer’s requirement. 310S has excellent resistance to oxidation under constant temperatures to 2000 F degree. Cyclic conditions reduce its oxidation resistance, and a maximum operating temperature of 1900 F degree is generally recommended if cycling is involved.

Having a lower coefficient of expansion than most 300 stainless steels, 310S may be used in operations involving moderately severe thermal cycling, such as rapid air cooling. It is not usually recommended for liquid quenching. Although 310S has less resistance to absorption of carbon and nitrogen than the higher alloys such as 330 and 333, it is widely used in moderately carburizing atmospheres such as encountered in petro-chem plants.

Because of its high chromium and medium nickel contents, 310S may be used in atmospheres containing moderate amounts of sulfur.

Availability – Stainless Steel 310S

Seamless Pipe 1/2″

Chemical Composition – Stainless Steel 310S

C Cr Mn Mo Ni P S Si

Max Max Max Max Max Max

0.08% 24% – 26% 2.0% 0.75% 19% – 22% 0.045% 0.03% 0.75%

Design Features – Stainless Steel 310S

Austenitic stainless steel with excellent high temperature oxidation resistance.

Good for continuous exposure to 2100 F degree, intermittent service to 1900 F degree.

Better elevated temperature creep strength than the 18-8 grades.

Good resistance to both carburizing and reducing environments.

General corrosion resistance better than Types 304 and 309.

May be susceptibe to chloride stress corrosion cracking.

Ease of fabrication.

Typical Applications – Stainless Steel 310S

Sulfur bearing gas atmospheres

Molten salt applications

Heat exchangers

Heat recuperator tubing

Tensile Requirements – Stainless Steel 310S

Tensile Strength (KSI) : 75

Yield Strength (KSI) : 30